The size of some transistors is 10,000 times smaller than the width of a human hair, and others have more than 50 billion tiny transistors in them. They are manufactured on manufacturing floors that may be seven storeys high and span the length of four football fields, thanks to the use of ultraclean technology.

Contemporary economies rely heavily on microchips, which are in many respects the lifeblood of the modern economy. They provide power to computers, cellphones, automobiles, appliances, and a plethora of other electronic devices. However, since the epidemic, the world’s demand for them has skyrocketed, causing supply-chain disruptions that have resulted in a worldwide scarcity of the commodities.

The result is inflationary pressures and concerns that the United States is growing too reliant on chips manufactured elsewhere. The United States is only responsible for roughly 12% of worldwide semiconductor production capacity, with Taiwan accounting for more than 90% of the most sophisticated chips.

Intel, a Silicon Valley behemoth that is attempting to regain its long-held leadership position in chip manufacturing technology, is placing a $20 billion wager that it will be able to assist alleviate the chip shortage. Building two additional facilities at its chip-making complex in Chandler, Ariz., will take three years to complete. It has also just revealed plans for a possibly larger expansion, with new locations in New Albany, Ohio, and Magdeburg (Germany), which would take three years to construct.

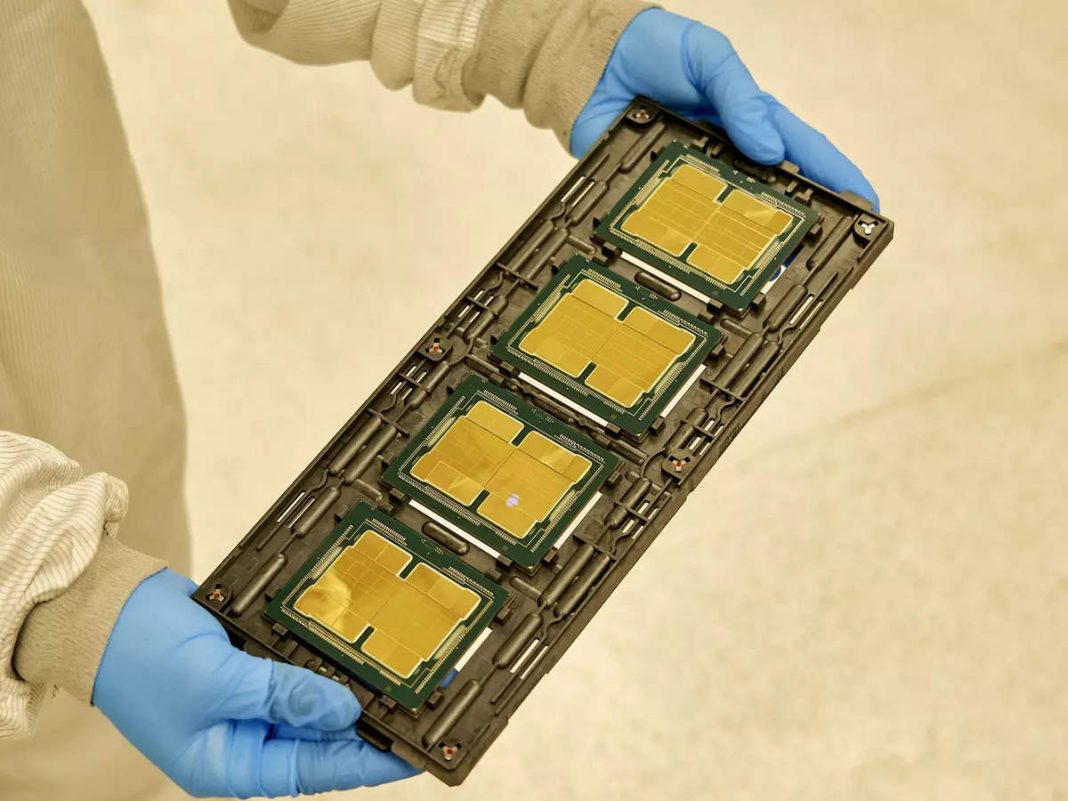

Chips, also known as integrated circuits, first appeared in the late 1950s, replacing the cumbersome individual transistors. Many of those small components are manufactured on a piece of silicon and then joined in order to function as a whole. The resultant chips are used to store data, amplify radio signals, and conduct other activities. Intel is particularly well-known for a kind of chip known as a microprocessor, which is capable of doing the majority of the computing duties of a computer.

Intel has succeeded in shrinking the transistors in its microprocessors to dizzyingly small sizes. However, the competitor Taiwan Semiconductor Manufacturing Company is capable of producing even smaller components, which was a major factor in Apple’s decision to use it to manufacture the circuits for its next iPhones.

With such victories by a Taiwanese-based company on an island that China claims as its own, there are signs of a widening technological gap that could put advances in computing, consumer electronics, and military hardware at risk from both Chinese ambitions and natural threats in Taiwan, such as earthquakes and drought, according to the International Technology Gap Report. And it has shone a focus on Intel’s attempts to regain its position as the technological leader.

They have a lot of things to do. Approximately 890,000 cubic yards of soil are planned to be removed during the foundation excavation process, which will be carried away at a pace of one dump truck per minute, according to Dan Doron, Intel’s construction head.

Construction of the Burj Khalifa in Dubai, which is the world’s tallest structure, is expected to use more concrete and steel than the foundations of the proposed project, which will be more than 445,000 cubic yards of concrete and 100,000 tonnes of steel.

Mr. Doron said that some of the cranes being used in the construction are so enormous that more than 100 vehicles are required to transport the components to be assembled. The cranes will be used to lift a variety of items, including 55-ton chillers for the new fabrication facilities.

Since taking over as Intel’s CEO a year ago, Patrick Gelsinger has advocated for federal funding for fab building and tax deductions for equipment investment in the United States Congress. Intel’s expenditure risk will be managed by a focus on the creation of “fab shells” that can be supplied with technology to adapt to market shifts, according to Mr. Krzanich.

Mr. Gelsinger will have to follow through on his promise to manufacture chips made by other firms in order to alleviate the chip shortage. However, a single business can only do so much; devices like as phones and automobiles need components from a wide range of companies, as well as older semiconductors. In addition, no nation can compete on its own in the semiconductor industry. The chip industry will continue to depend on a complex worldwide network of enterprises for raw materials, production equipment, design software, expertise, and specialist manufacturing, even though increasing domestic manufacture will help to mitigate supply concerns.