In the small Georgia town of Swainsboro, the first item that greets visitors is a black-and-white photograph that was discovered in an antique shop by Steve Hawkins, one of America Knits’ founding partners.

One of the many textile mills that formerly littered the landscape, as well as the employees who worked away on its machines and provided the fuel for the local economy, are shown. The setting evokes the glory — and, according to Mr. Hawkins, the promise — of clothing manufacturing in the rural South.

Companies like America Knits will put the United States to the test to see whether it can reclaim some of the industrial output that has been lost to China and other nations in recent decades. When it comes to employees whose employment have been eliminated as a result of globalisation, the answer has been a source of contention. However, as a consequence of the supply-chain snarls caused by the coronavirus epidemic, it has become acutely real from the perspective of the customer as well.

Mr. Hawkins’ firm, which was started in 2019, employs 65 people who make excellent T-shirts using cotton that is farmed in the area. He anticipates that the number of employees will rise to 100 in the next months. If there is to be an industrial revival in the region, it will be a lonely one for the time being. He claims that he is the only one who is insane. “I’m the only one who is crazy,” Mr. Hawkins says.

However, he believes that the time has come to bring manufacturing back to the United States from abroad – a process known as onshoring or reshoring.

Some business heavyweights are eager to put that concept to the test, if not for completed items, then at the very least for critical components.

A general motors spokesperson said in December that the company was contemplating investing upwards of $4 billion to increase electric car and battery manufacturing in Michigan. Toyota announced plans for a $1.3 billion battery facility in North Carolina, which would employ 1,750 people, only a few days later.

According to a statement released in October, Micron Technology intends to spend more than $150 billion in memory chip production, research, and development over the next decade, with a part of that investment to be spent in the United States. In addition, the South Korean powerhouse Samsung said in November that it will spend $17 billion in the construction of a semiconductor factory in Texas, making it the company’s biggest investment in the United States to date.

Former President Donald J. Trump made bringing manufacturing back to the United States a central focus of his administration, which put taxes on imports from friends and adversaries, launched a trade war with China, and obstructed or revised trade deals in the process. Despite this, there was little change in the balance of trade or the willingness of corporations operating in China to divert investment to the United States throughout the period under review.

Although it has been a while since the pandemic first broke out, attempts to shift production have quickened, according to Claudio Knizek, global head for innovative manufacturing and mobility at EY-Parthenon, an international strategic consulting business.

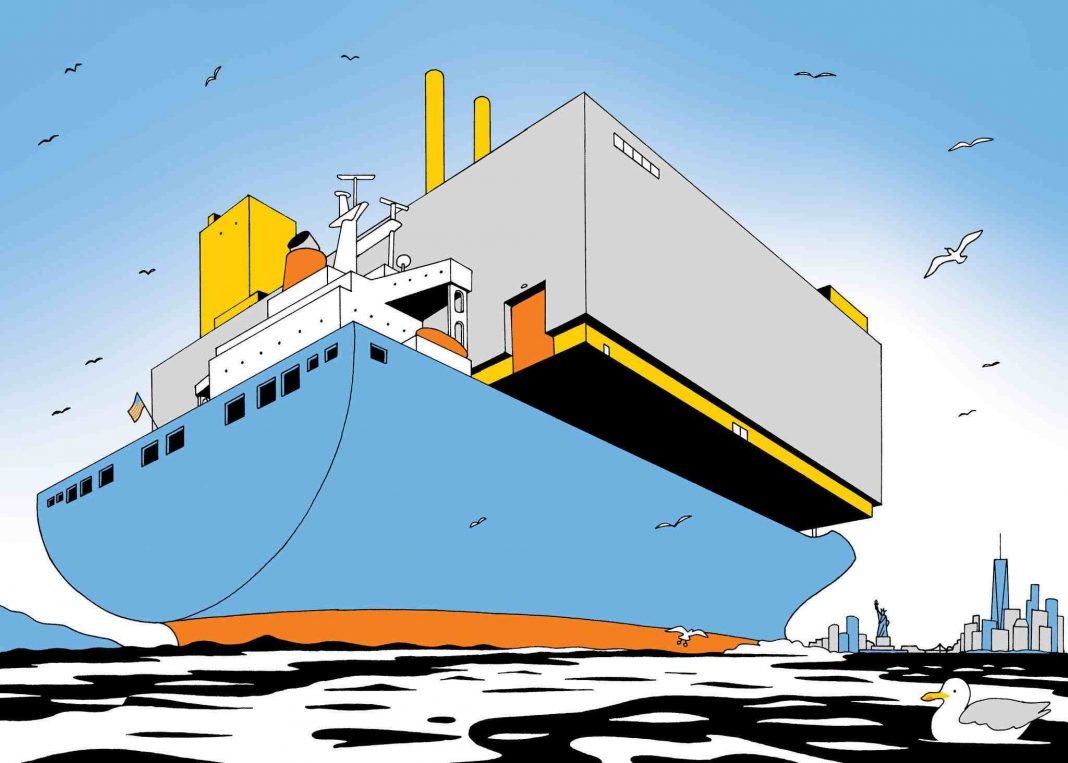

Over the years, the United States has relied on Asian manufacturing mostly in China, which has been disrupted by shipping delays and soaring freight charges – when shipping capacity can be available at all.

Backups at overburdened ports, as well as difficulties in procuring components and completed goods in a timely manner, have prompted several corporations to consider shifting manufacturing capacity closer to customers.

Instead, the 12-year-old company plans to establish a facility in Port Gibson, Miss., in 2022, replacing its current location. Fabric will be cut in Winnipeg and delivered to Port Gibson, where it will be stitched into items such as coats and sweaters, among other things. Ms. Land said that the plant would be fully automated, which will allow her firm to keep prices under control while competing with abroad workshops.